Reprap Next.

What is it?

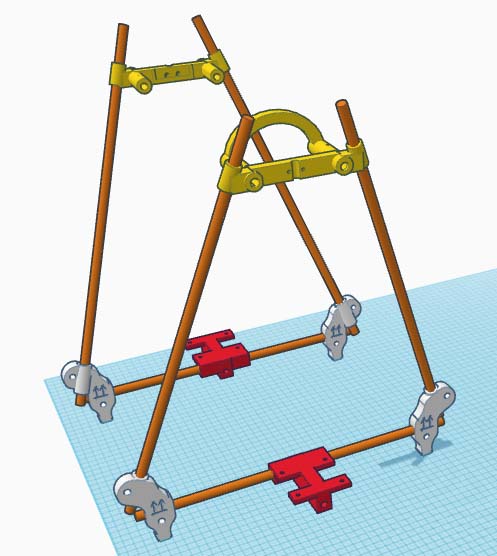

The idea is to alter the Reprap Prusa i2 at an absolute minimum cost, in order to get 21-24 cm of print height. Note, that, unlike in Reprap Pyramid, we are not going to purchase longer smooth rods: we'll reuse the 30 cm ones. We are only going to need some (not all) new plastic parts and new threaded rods ($3-4 on a local construction market). The rest: hardware, electronic components etc. - is the same.

On this site you will find detailed assembly instructions, STL files to print plastic parts and even pre-configured software.

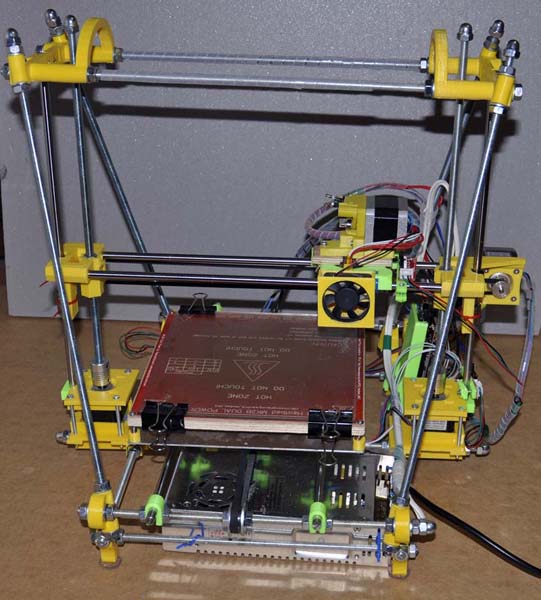

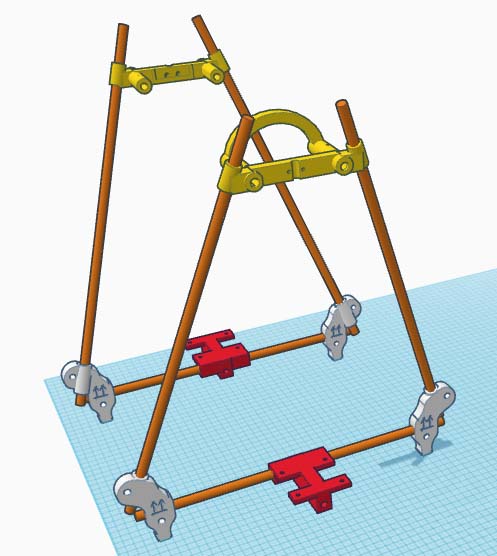

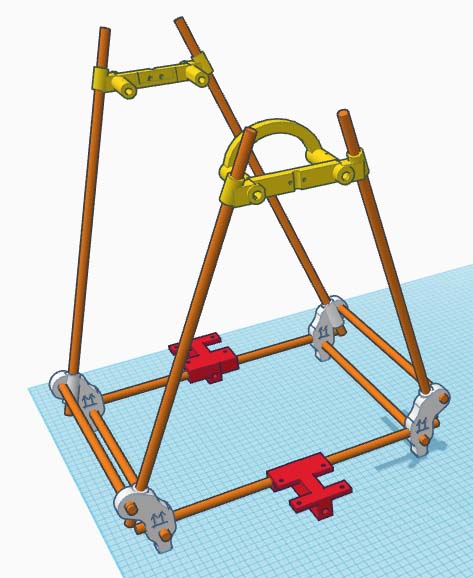

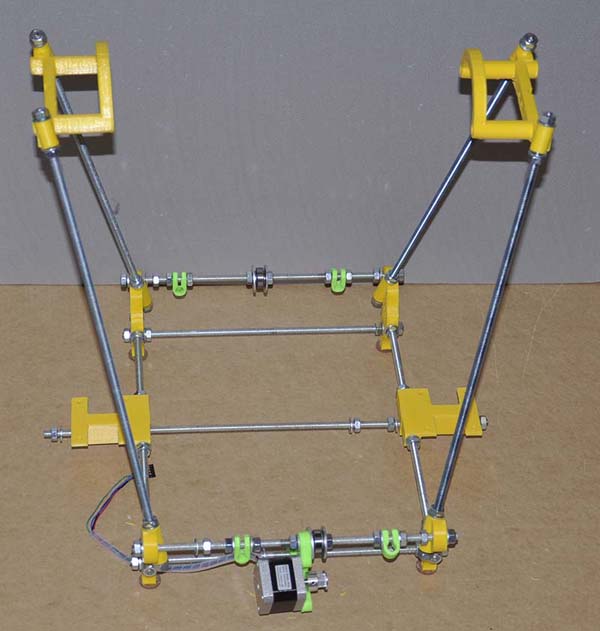

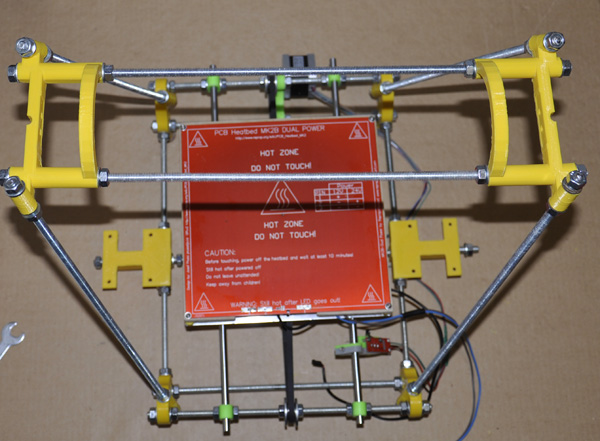

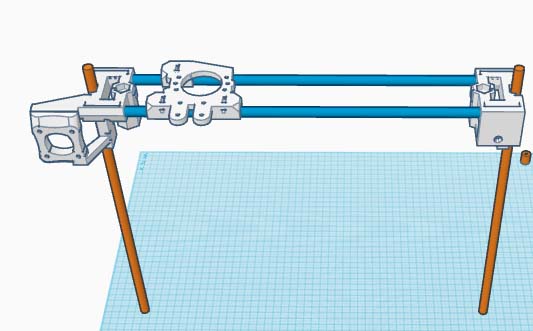

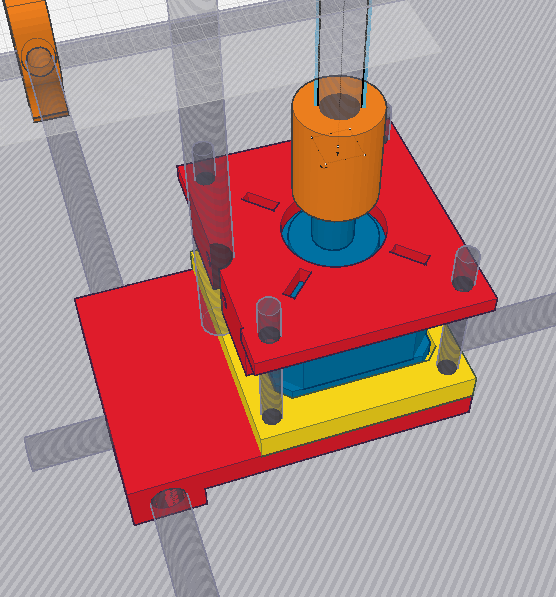

As you can see on a picture, the framework of "Next" was turned in side out (compared to Prusa), to allow the extruder to move without hitting obstacles. Also, motors were moved down to use the space below the hotbed. Also also :) the top-horizontal threaded rods were moved a bit wider: now the extruder can move between them, which means few extra centimeters of the overall printing height.

Assembly specifics.

Unlike with Prusa i2, when assembling Reprap Next, you will have to pay close attenton to angles and lengths of frame elements, as it is much easier to get a twisted pyramid then a twisted prism. This is the only disadvantage, and it will hardly take more then extra thirty minutes.

For your convenience, I have included some extra parts, ones that are not part of "standard" printed set: the Arduino holder, SD reader holder, fan holder and so on. Feel free to ignore them if you have a better solution.

Non-printed parts.

BOM, list of matherials.

As I used Prusa i2 as a prototype, the list of (non-prnted) parts is mostly the same.

Bolts and nuts. As threaded rods are 8mm, so are nuts. If you feel like spending more, use nuts with rubber ring inside,

they handle vibration better. However, if a regular nut is tightened well enough, it holds, too.

For other cases, 3mm bolts and nuts were used. The only exception is set of long bolts holding together Z-motors' "sandwiches",

they are 60x4mm:

Washers. Used always. Not sure it is vital, so use your own judgement.

Bearings. 10 LM8UU (Asia) or LME8UU (US, Europe). Linear bearings, preferably, high quality. Speaking of quality:

most demanding are linear bearings and smooth rods.

3 608 "roller skate" bearngs, "6082RS" "sealed", or "608ZZ" "shielded". Again, try finding good ones, at least, not used ones.

Threaded rods. Reprap Next uses cheap 8 mm threaded rods made of iron (not stainless steel).

I don't see any reason using high quality high precision here, also they are harder to cut.

Х: 2x38 cm.

Y: 4x30, 1x44 cm.

Sides of a pyramid: 4x45 cm.

Uper pair: 2x44 cm.

Z-motors: 2x35 cm.

Smooth rods:

Х and У: (40.5 + 40.5), (42 + 42), Z: 2x35 cm. (same as Prusa i2).

Belts.

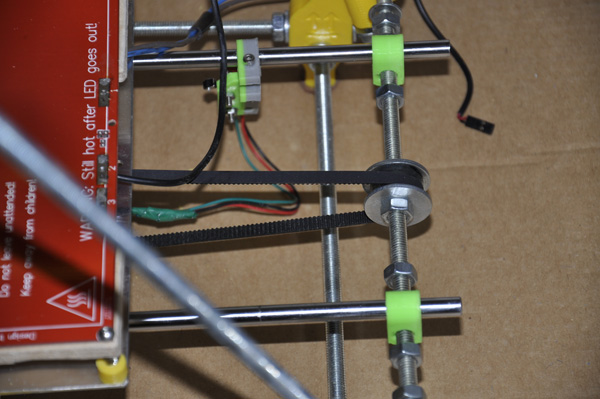

GT2 toothed belt (you can also use T2.5, just make sure pulleys are same type).

T5 can be used but not recommended.

2 16-tooth pulleys to work with GT2 belt. It is possible but not recommended, to use 12-tooth ones.

The hole on a pulley should match the motor's 5mm.

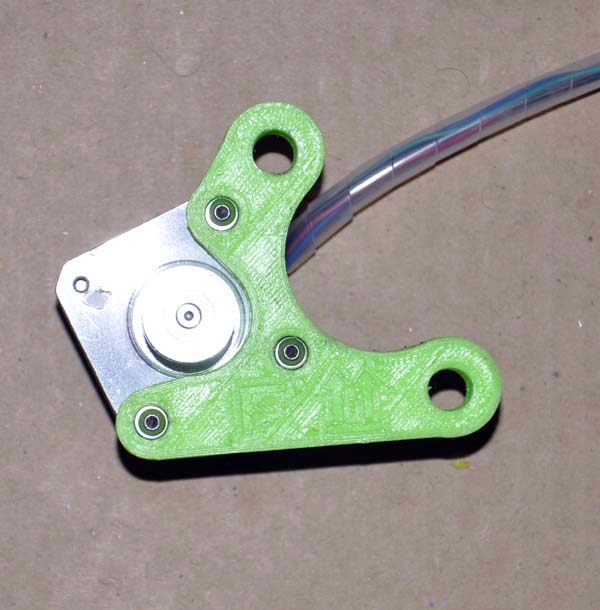

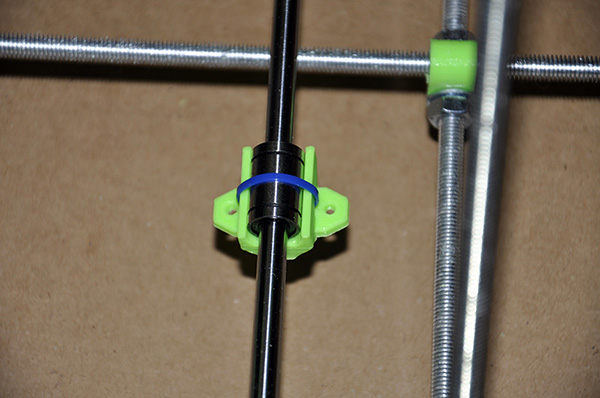

Coupling. I suggest you forget about Prusa's plastic couplings once and forever. They are unreliable. Buy an aluminum ones on Ali or eBay, they look like a cylinder with a spiral cut:

Keep in mind that couplings can differ, you need holes on it to match 8mm on one side and 5 mm on the other (a threaded rod and a motor).

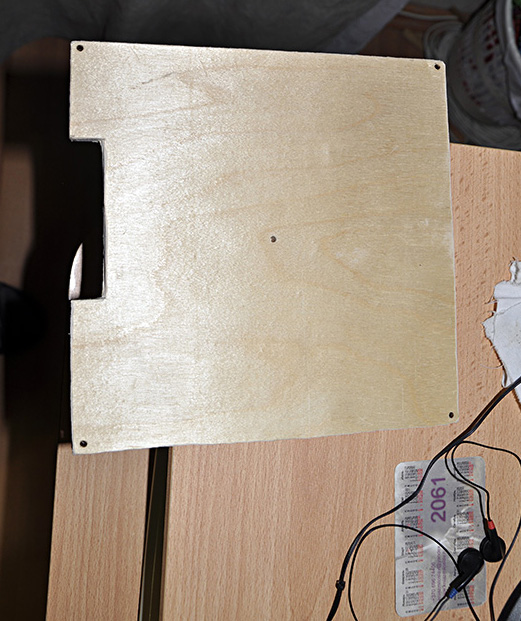

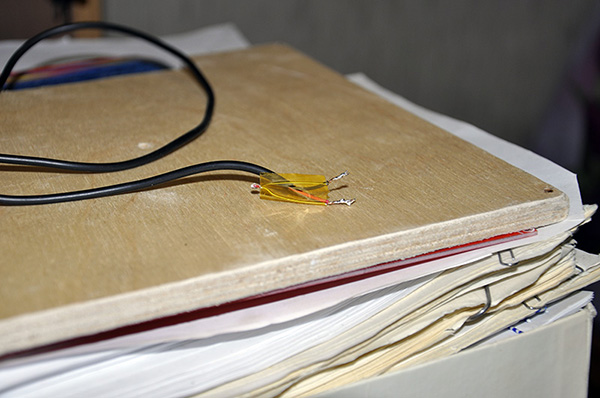

Plywood. 225x225 (You cam make it a bit larger) x6 mm (or 8 mm) plywood is used to insulate the bottom side of a print bed. On reprap forums there are some alternatives, but plywood is still the best choice.

Glass. Borosilicate glass is the best choice. Often you can see people using mirrors etc., but I don't recommend it. An interesting alternative is sitall glass, plastics sticks to it very well. I have tried and it worked, but in my opinion, the best results can be achieved on borosilicate glass sprayed with hair spray.

If you are going to use my extruder, add a driver wheel (mine is from Ali):

and a 623ZZ bearing (or similar, 3x10x4 mm).

Plastic parts. STL files can be ordered here.

Where to order parts.

Leaving aside small suppliers, you have two options: aliexpress.com and ebay.com. Both sources are adequate, and have surprisingly low prices. Of course, sometimes, especially on Ali, you will find a 2 dollars item asking 1000 dollars for delivery... well... Just look for better alternatives :)

As for bolts and nuts, use local construction market.

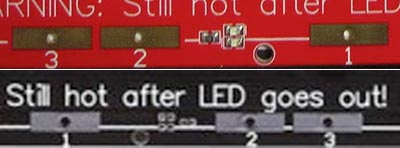

A fair warning.

Being quite reliable, Repraps are nevertheless as simple as a brick, particularly it concerns safety systems, that are simply not there. If it catches fire, it burns, with or without your appartment, depending on your luck. Frankly, there are tens, maybe hundreds thousands of Repraps, and I never heard about such accidents, but... But enthusiasts found a combination of conditions for it to combust, so it is THEORETICALLY possible. You can find more info on forums, a good starting point is reprap.org.

Frame.

Assemble sides of a frame, two of them.

An important note about plastic parts. Any reprap assembling guide begins with "take a drill". See, printer is not a precise tool, and 8 mm hole, or especially a 3 mm hole will be smaller, as some plastic is squeezed to the side. Use drill, file, or a cutter.

Note, that the set of STLs for printed parts includes two (alternative) "frame vertex" parts: one with handle and one without. Choose whichever you like.

As you cn see from the photos, parts are being held together with bolts and nuts. Make it tight, but not too tight: if too much force is applied, plastic can crack. Also, don't make it tight just yet: you will need to be able to move parts around later to make frame symmetric.

Depending on how easy or how tight rods are moving in holes, you will have to apply some force... which is really not required. Make holes wider with the drill, it will make adjusting the frame easier.

Reprap has two horizontal rods on each "Y" side, it makes the frame stronger, besides, rods can be used to attach motors, and other peripherial equipment.

Here are two sides and the back assembled together. I call the "back" side one where the Y-motor will be installed.

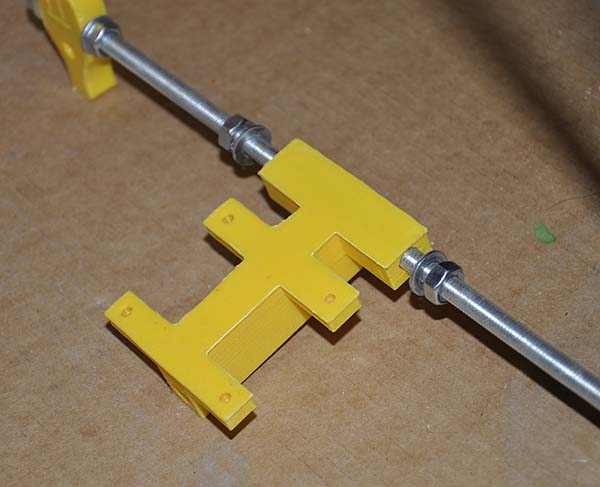

This is a holder of a Z-motor. Later, when you tighten all nuts, it should be exactly at the middle.

Add the central horizontal rod:

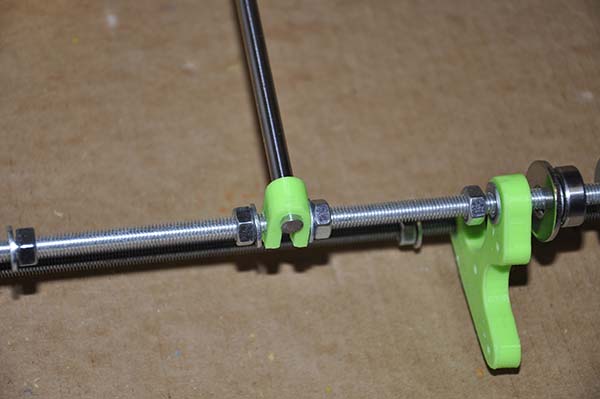

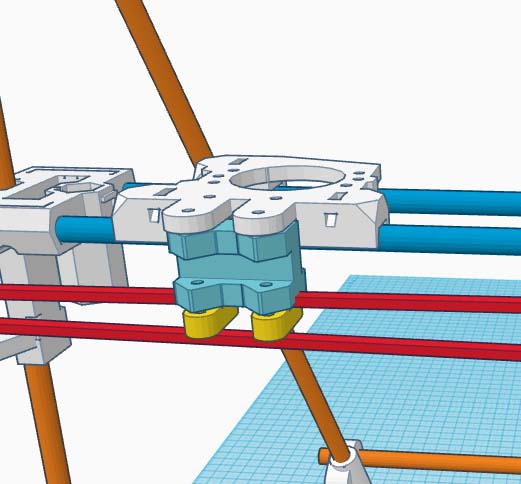

Note the way a bearing is installed. A central part of it is fixed with two small washngs, and then we add two larger washings outside.

Prusa i2 has so called "bearing guide", which I strongly discourage you to use, as it is much less reliable then the "sandwich" of a bearing and two pairs of washers. Thin plastic has a tendency to fall apart at the most inconvenient moments.

Adding Y-motor holder and the opposite part (similar, except instead of a motor holder, we have a bearing to guide a belt). You can attach the motor now or you can do it later.

Add upper horizontal rods. We use two rods in the upper part of a pyramid, it makes the frame more rigid, plus it is convenient to carry the device holding it by these rods.

Y axe.

Our printer has 3 axes. First, the print bed moves forward and back, along Y axe. Second, an extruder moved left-right, along X axe. Finally, as the printing proceeds, the extruder moves up along Z axe.

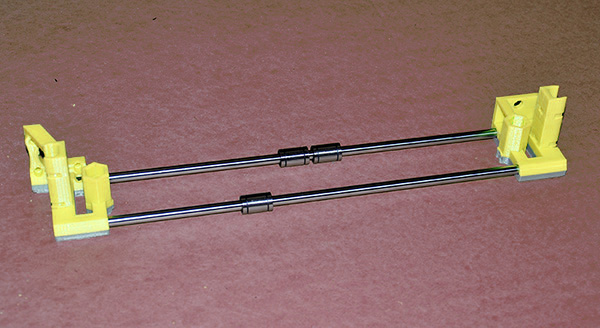

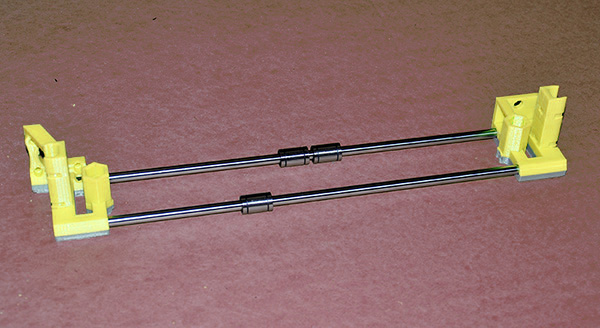

Add smooth rods for Y-axe.

On the next picture you can see linear bearings on a smooth rod. We attach plastic parts to linear bearings using zip ties. Later on, they will be attached to the bottom side of a print bed.

On one rod we place one bearing, and two of them on the other rod.

Installing Y axe and print bed.

It is possible to add print bed now or later. An advantage is, X axe will not interfere as it is not there yet. A disadvantage - in future, the Y axe will be on our way :) In this manual I am going to install Y axe and print bed now, while in Prusa i2 manual I used the different order ofassembling.

Assembling the print bed.

A print bed is just a heated surface. We need to keep it hot during printing, as plastic will not stick to cold surface. Therefore, we are only interested in keeping the upper side of our assembly hot. However, if we do not insulate the bottom side, it will loose heat as well. We use plywood for insulation and for extra rigidity.

Note that there is a discrepancy in order of things here, I am going to explain soldering wires to print bed later in "electronics", but to assemble the print bed you need to solder wires first.

Heated surface:

As was mentioned, to prevent loosing heat, we insulate the bottom side of our heated bed with the plywood. The plywood used should be between 6 and 8 mm thick and need to be 2-5 mm wider than the heated surface itself. That surface can have different sizes: 20x20, 21x21, 22x22... so I can not provide you with exact dimentions: use the ruler. Also, as you can see on the picture, there is a chunk of plywood removed on one side, to make space for wires.

Make sure you measured everything with precision and drill four holes for bolts and one in the middle for the thermistor. Holes for bolts should be wider then bolts themselves, allowing them to slide through, if bed is pushed down. Otherwise, if an extruder accidentally goes too far down, it can break the glass covering the hotbed.

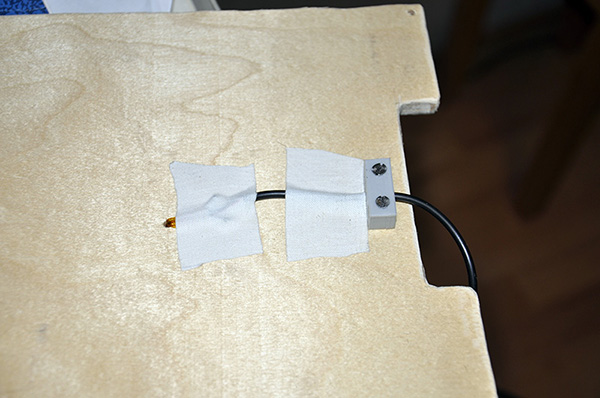

A termistor should get through the plywood and into the hole in the middle of heated surface, fo precision is required indeed.

As usual, there is no info on how to fix the thermistor and its wires. First, I used tape, but it was not secure enough. Then (tape is still there, but it is not required anymore) I used one of plastic belt holders to hold the wire against the plywood. Finally, a know-how: use tooth picker's fragments to lock the thermistor in the drilled hole.

When soldering thermistor wires, mke sure they do not touch each other. I used heat resisant tape.

Installing the Y-motor.

Cut off the toothed belt a bit longer than the length required. Install the Y-motor. The belt should go under the belt holders and should be tightened.

Finalizing the heated bed assembly.

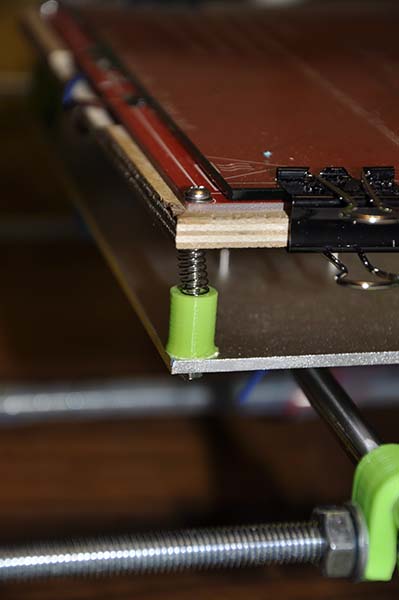

Screw together all layers of a resulting sandwich using long bolts with springs. The idea is to be able to use bolts to bring corners of the heated bed up or down, making sure the distance between the bed and the tip of an extruder is always the same, regardless how you move it by X or Y axes.

Note the use of presentation clips to hold the glass in place.

In my version of a printer, springs are pushed up mith tiny plastic cylinders. This part is not mandatory, it is just my springs happened to be too weak, so I had to compress them additionally.

The bed, view from top, bottom and sides. Belt is not tightened yet.

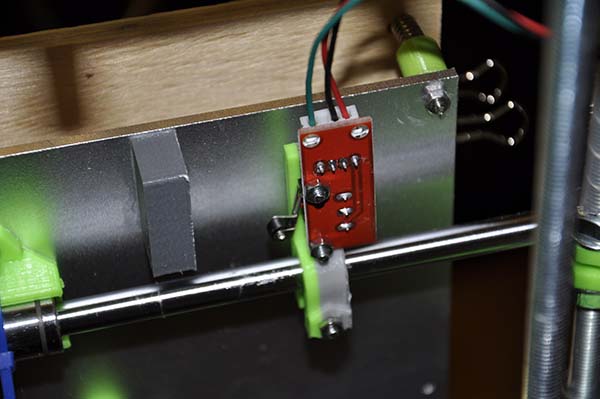

Y-stop.

A "stop" is just the button the hot bed presses when trying to move too far, towards the area of negative coordinates. In case of the Y-axe, we need to attach the Y-stop to a smooth rod under the hot bed. On the next picture you can see the hot bed, view from the bottom.

Note that you are free to place the Y-stop on any side of the hot bed, and to adjust it to "catch" the edge of a heated bed, the bearing etc. I cheated: glued the plastic cube to the bottom of a hot bed, so the stop is triggered by it.

More about the side you set the stop at. As I mentioned, "stop" is just a button. All it does is limiting the bed's moves towards the negative coordinates. There is an option, in software, to use pairs of stops, limiting the bed in both directions, but most people do not bother, as they count on the fact that no one will try printing parts that are too large.

The only limitation is, we want our printer to print a part we want, not its mirror reflection. Accordingly, if you want to set the X or Y-stop on the other side, by all means, do it. You will be able to test the result later, and if you find that the printer produces the mirror reflection of what it should, you will have to move stop of a second (X or Y) axe, or to make changes in software (they have special flag for it).

When you move the stop to the other side of an axe, the printer still looks for it in the old (now wrond) direction. So, either change it in software, or simply unplug the motor, turn wires up side down and plug it back. The motor will change the direction.

All I said above applies to X and Y axes, of course, as Z-axe's zero is always at the bottom.

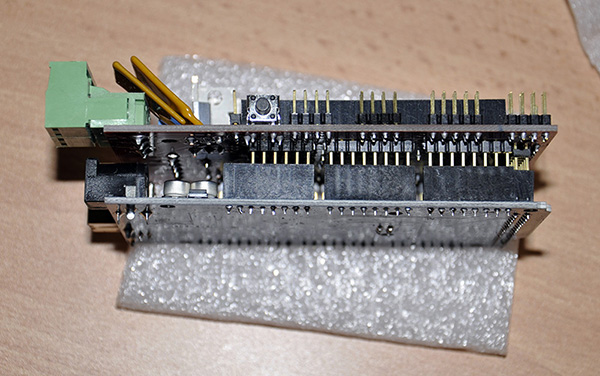

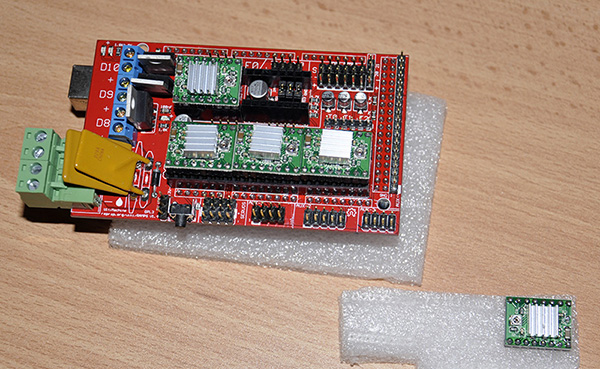

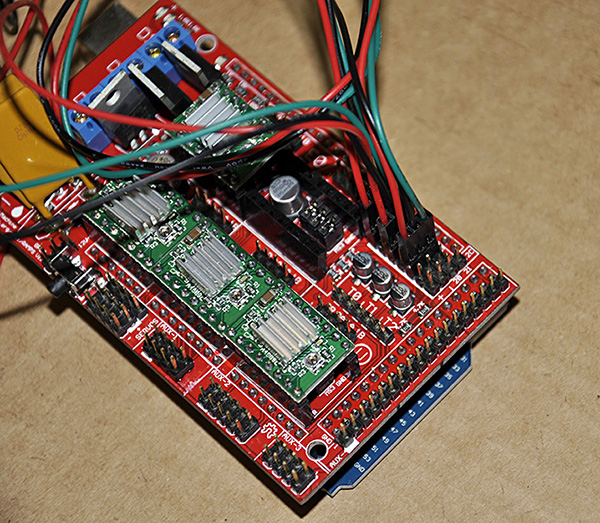

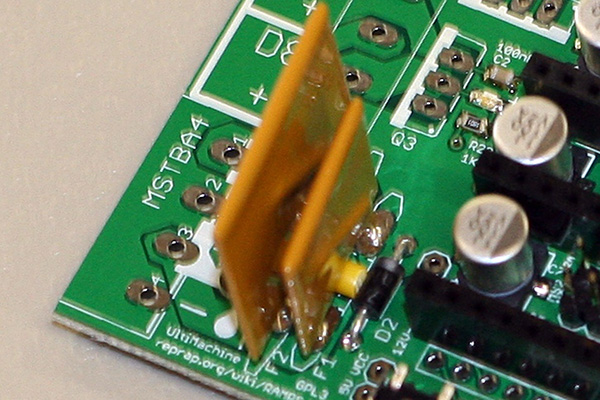

Installing Ардуино and RAMPS.

Reprap uses Arduino Mega and RAMPS Pololu. As for RAMPS, it is rather simple: it should be plugged into Arduino itself. Now, where should we place Arduino? As usual, Reprap standard is missing.

We have few options, as our printer has few sides. I chose the option shown on the following photo. As there is no default Arduino holder, I had to design my own version of Arduino Holder, it "clicks" onto the horizontal rod and is attached to the side of the pyramid with zip lock.

I have two versions, one with fan (Arduino Holder with Fan) and one without it (above). According to my experience, shields and mosfets do become hot, and regardless the fact that they are still able to work, cooling them is a good idea. There are different ways of installing fans, I connected them to the RAMPS's D9 (extruder fan) and to PSU's 12V (Arduino cooler). Use 30 mm fan for Arduino/RAMPS and 40/45 mm for extruder.

X axe.

Depending on the version of your reprap, X axe uses 3 or 4 linear bearings. Smooth rods are squeezed in holes in X-idlers, and you may need the 8mm drill to make those holes wider. On one side, you do not want plastic parts to be loose, on the other, if you apply too much force, plastic can crack.

Note that in Reprap Next the X motor holder and idler plastic parts are turned up side down, compared to what you used to see in Prusa i2. The reason is, it gives us few more centimeters.

Right and left sides are different, as one has motor attached and the other only has bearing.

X-motor is mounted using bolts, and (same as with Y and Z motors) you may want to install something soft between the motor and plastic, to act as vibration absorbant. I personally don't believe it has any sence, but some folks on reprap forums have different opinion. Use foamed plastic if you choose to do it.

Note, that instead of printing our own X-carriage part, we used the i2's one, and added a small separate connector to move the belt lower.

Z-axe.

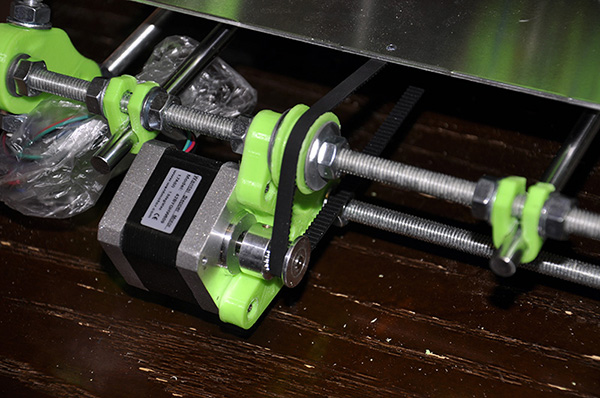

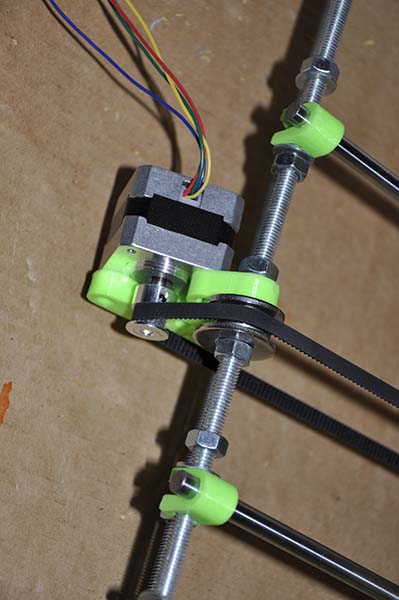

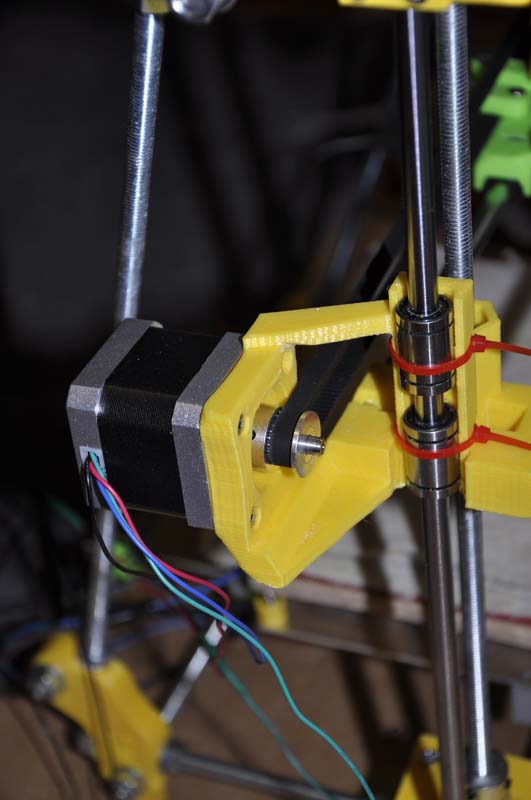

In Reprap Next we install Z-motors at the bottom of Z axe. As the result, they occupy space below the hot bed, increasing an overall height of print area.

Earlier when assembling the printer, we added the plastic part that was intended as a Z-motor holder (two of them, as we have two Z-motors). Z-motors are connected in parallel and wired to the same socket of RAMPS, by the way.

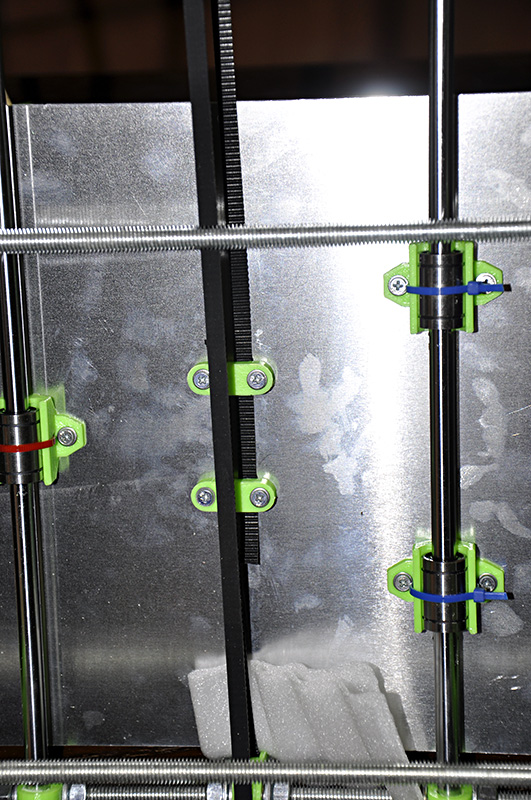

As you can see, we use two linear bearings on each Z-axe. We need it to reduse loft, as it could otherwise produce print artifacts (aka ghosting).

As usual, we use zip locks to hold berings in place.

It is also important to keep track of where is the right and left sides. Well... not that it is vital, as you can always set firmware flags or rewire motors, but...

A smooth rod guides the axe and it should be outside the motor holder.

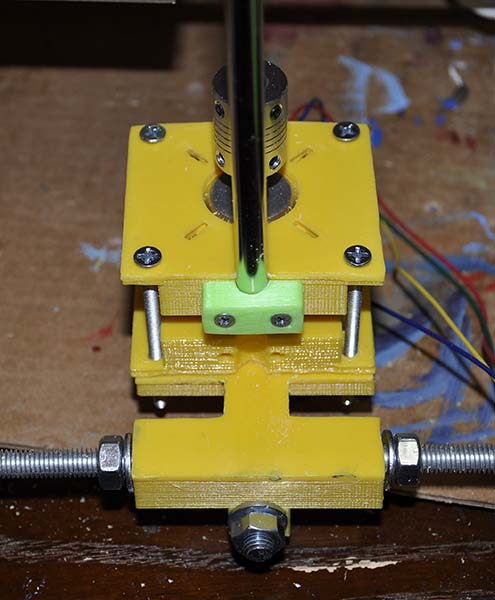

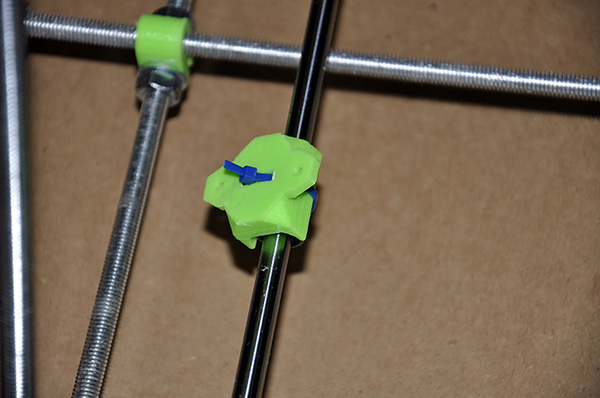

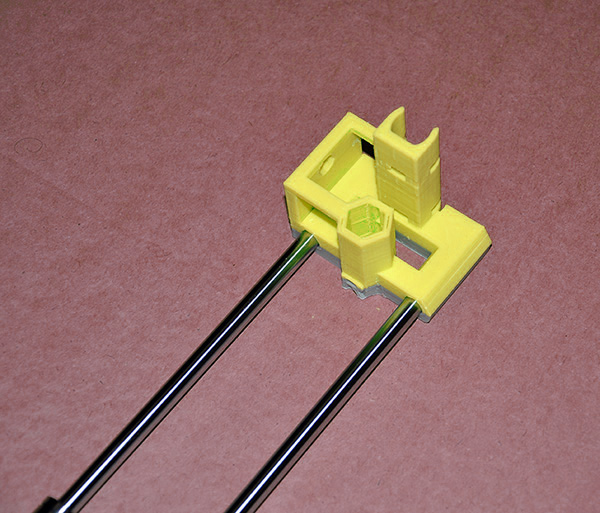

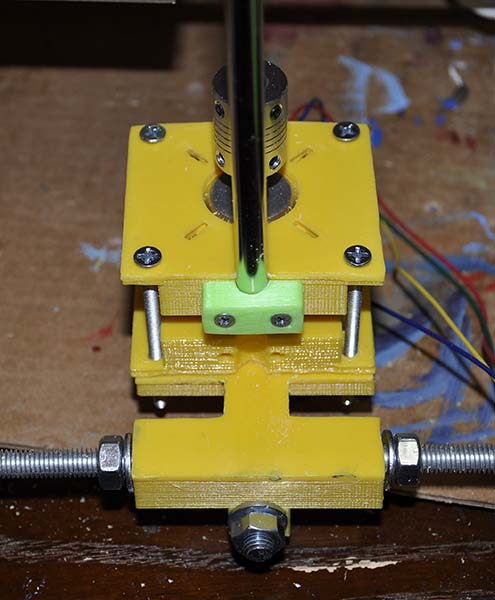

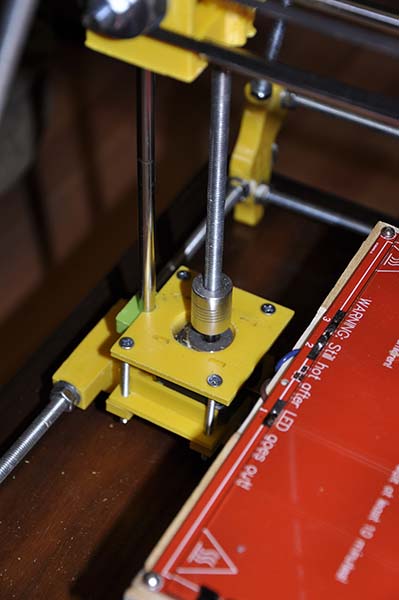

Let's take a look at Z-motor holder. The entire thing looks like a sandwich:

Parts are designed in such a way that the motor can move slightly (before you tighten nuts). It allows us to adjust Z axe to be strictly vertical and parallel to threaded rod. Otherwise, considering the large distance the extruder travels up and down along Z axe (compared to Prusa i2), the threaded rod can get jammed, not being able to spin.

A smooth rod is fixed both on top and at the bottom:

To fix it, we (re)use parts from Prusa i2: the rod clamp (though we use 4 instead of 2).

Installing motors.

We are going to use five (identical) stepper motors NEMA-17. I believe this is an ideal solition, however, there are nuances. First, NEMA-17 is not a brand, but rather a type of the motor, so anybody can make it. It means - as with any electronic component - that there is a chance to purchase cheap low quality junk. You can read customer reviews for a particular seller, but there still is the risk.

Second, motors differ by the torque. You can find all kind of details on forums, briefly: what you need is maximum force with minimum heating. The longer the motor body is, the more torque it can produce, but I advice against becoming fanatical here. Let me make your life easier: my motors are 4 cm long. Five is ok. 3 is less than you need. If you have no choice, you will probably be able to reduce (in the software settings) the speed of print to get away with weak motors but why would you do it?

If you think that measuring motor power in centimeters is not scientific enough, look for the current. 1.7 amperes is ok. 0.5 - insufficient.

It is a common belief that motors vibrate and that vibration should be suppressed in order to not pass it to the printing head. In theory, this can lead to ghosting, in reality, it is not the most common reason for the ghosting, and not the most frequent one. But yes, it can reduce precision of the printer. Therefore, we need to add something soft between the motor and the motor holder, in my case a plastic foam is used. Z-motor does not spin that fast, so it is thin; I am going to use thicker ones for X and Y motors.

Now we can install Z-motors. Note that it is up to you to decide in which direction wires will go, it is not part of the spec. My choice is great, but if you have your reasons, feel free to go another way.

Generally, the idea of Reprap wiring is to put wires closer to frame and then to wrap them together to produce something neat. So I am placing wires closer to the frame from the very beginning.

There are, of course, exceptions: wires coming from objects that move (hot bed and extruder) shouldn't be attacher to threaded rods right away, you need to leave some free wire for those parts to be able to move. Later on I will show you how to hide those wires under plastic coverings to make the printer look more professional. An item I bought on Ali Express was not easy ti find unless you know the sacred name of it which was "Durable Spiral Wire Wrapping Tube Manage Cord for PC Computer Home Cable Lowest Price", please do not ask how I was able to figure that out :)

Note that using this sort of wrapper it is possible to make wires bend in one particular plane, so as parts of a printer move relative to each other, the wire does not cause any problems.

Z-motors turn the threaded rod (М8, eight mm in diameter), which allows us to move the X-axe up an down, together with the extruder. First, put the nut on the very tip of a rod. Then insert the second nut into the hole in the plastic part (motor holder or idler). The idea is to fix the plastic part between two nuts, one on top, one on the bottom. Screw in the rod carefully: we need to have as little free space between nuts as possible. Two mm is ok, but no more.

Let me repeat again: default Reprap's couplings is a BAD solution. Use aluminum ones instead, they are cheap and way more reliable:

Ok, X-axe is installed, and of course, if should be horizontal. You can level it by turning individual Z-motor by hand.

Extruder.

Assembling the Extruder.

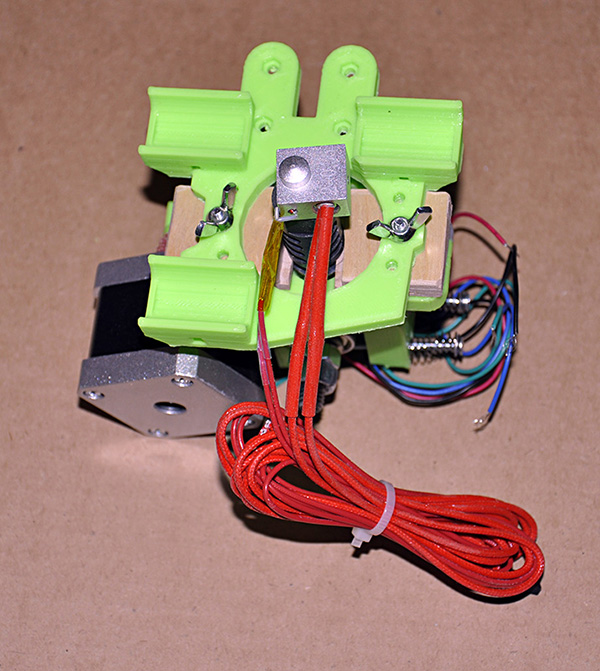

In our printer we are going to use my "ideal" Screwless Direct Extruder. If you do not like it, you can always use something else, but according to my experience it is as good as any other model, while much simpler and less demanding then most of them.

Important note: use 40 or 45 mm fan and corresponding plastic holder from the archive. However, I strongly recommend using a 45 mm fan and holder, as they produce less air flow and therefore, less affect the temperature of the heated bed.

Assembly details (that are very few as the device is very simple) you can see at the link above.

Установка головки экструдера.

Extruder head (hot end, J-Head) is installed on the support, made of the plywood. Sometimes metal one is used, or a printed one, made of plastic.

The wooden part is made of the plywood 8-12 mm thick (measure the cold end of your extruder, it should fit tight).

This is what an aluminium analog looks like, you can purchase it on eBay or Ali. Frankly, I am not sure it is better than the plywood one, as wood conducts less heat, so less heat will be transfered to plastic. On the other side, there is almost no heat there...

Installing the extruder.

The base of an extruder is attached to the X-carrier using bolts with nuts or (better) knobs.

Electronic components.

First of all, you don't have to be an expert to select proper components. All you need to do is typing in aliexpress something like "reprap termistor", to find out what termistors to use.

Soldering the print bed wires..

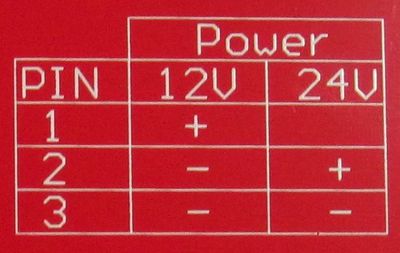

The theory can be found here. As you can see from pictures, I used MK2b Dual Power, one particular kind of the heating surfaces. If you have a different model, study the specs to learn the way to solder it. In my case, one wire goes to 2 and 3 (yes, we shortcircle them), and the second one goes to 1.

Wires are supposed to be attached underneath the heating surface, and they do not go through the holes: we are going to put the glass on top.

Here is (for my case only!) the guide, depending on what power source you use:

This is what contacts look like:

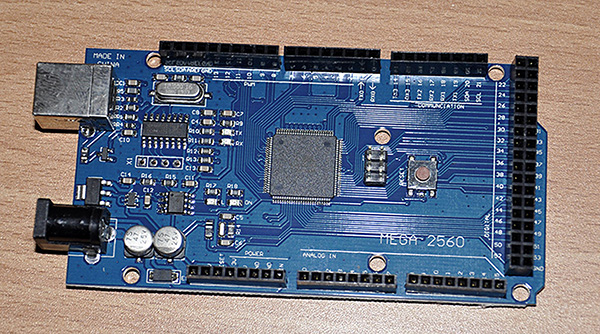

Arduino Mega.

There are many options in terms of the processor of our printer, some general purpose and some designed specifically for printing. I chose the legendary Arduino Mega. Yes, it is not specialized, so we have to add some componente instead of having them preinstalled. But if something burns out, you will not have to replace the whole board, also, Arduino has huge support outside the Reprap community, any question will be answered on forums.

By itself, Arduino can not produce enough current for motors, so we are going to use RAMPS, in my case it is RAMPS 1.4. It is being installed on top of Arduino, and then motor shields (below) are installed on top of it.

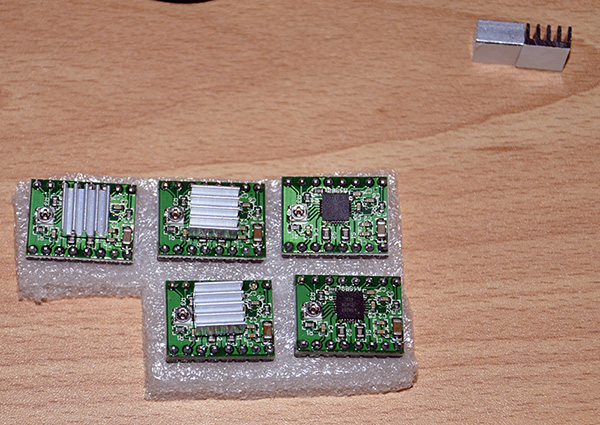

Motor shields.

Shields coltrol motors, there are four of them alltogether: X, Y, Z (two motors using one shield) and an extruder. If the printer uses dual extruder, we add the fifth shield.

Note that shields come with jumpers, and you usually need to install three of them under the shield, on RAMPS.

Important! On RAMPS you can see power jacks and yellow square details next to them. On motor shields you see a tiny screw - the head of a potensiometer. Now, this screw (usually refered as "pot") must be facing the direction, opposite to power jacks. If you put the shield wrong way, it will burn.

Wiring.

The following diagram shows the wiring from RAMPS to peripherial devices.

Additionally, I have attached fans' wires to RAMPS' D9 (extruder fan) and to PSU (any or two the power jacks on RAMPS, for Arduino cooler).

Wiring end stops.

As an example, I am going to use end stops, asuming that you can figure out the rest (motors and termistors). The diagram (above) is very straightforward after all.

As can be seen from a very straightforward diagram :) endstops are connected to a group of contacts on the upper right corner (of a diagram) in such a way, that we use every second pair: X-stop connected, skip the next pair, Y-stop connected etc.

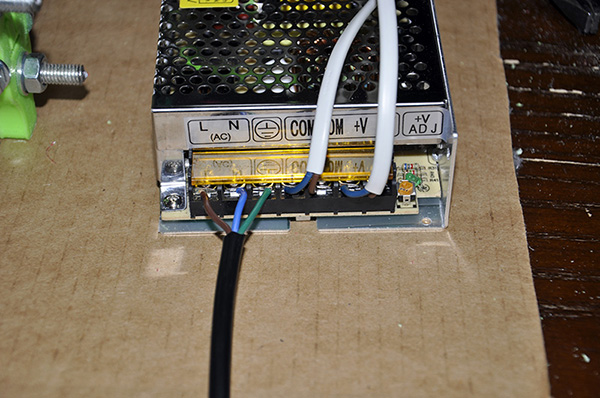

Attaching the power supply unit.

The next step is to provide the power to our assembly.

The power supply unit should provide 12 volts and about 300 watts, you can use computer power block or the one I used (see photo). Mine is more compact and fits under the printer. Now, if the PSU isn't powerful enough, there will be insufficient current, motors will skip steps and the hot bed will not be hot enough. As the result, your print will be ruined.

Voltage is low - 12 volts - nevertheless I expect you to know how to work with electricity. If not, please learn.

The PSU will go under the frame, attached to it with zip locks.

Anyway, four lines connected to PSU to RAMPS, polarity is vital. RAMPS provide power to (see diagram) Heated Bed, Hot End and (not on a diagram) you can connect an extra fan to cool shields themselves.

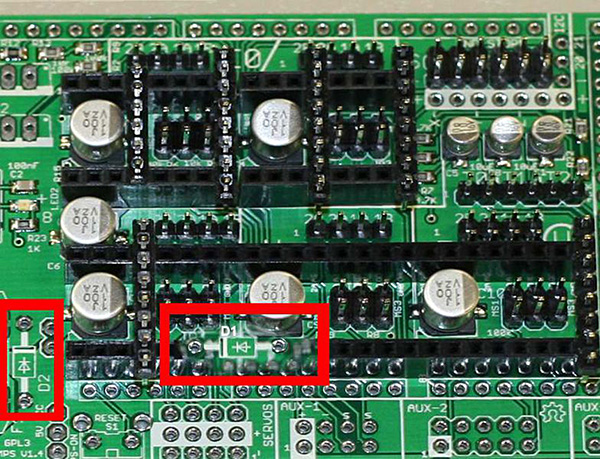

A logical question: where the Arduino itself gets its power? This is a rather complicated story, as (or should I say "as always"?) this is not part of specs. You can read some basics here. Briefly, we can get power from RAMPS and pass it to Arduino. To do it, we need to add two diodes (in theory, one might prove enough), then... Anyway, I almost bought those, fortunately, I found that my Arduino came with diodes already soldered in. See, what I bought was "Ардуино + RAMPS + shields" FOR REPRAP, so the seller took care of a potential problem.

It should be mentioned, however, that sometimes diodes are soldered in wrong way, sometimes (been there!) Arduino's voltage regulator breaks (because I placed the shield wrong way). So if your Arduino is damaged and refuses to use power via diodes, you still can get 12 volts (not higher!) from the PSU and send it to Arduino's barrel adaptor (the otherwise unused round jack). It should work.

Here you see places diodes should be soldered t:

This is what the diod looks like, note the orientation (the strip on its body):

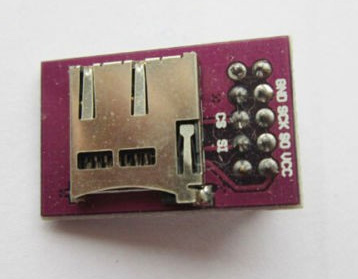

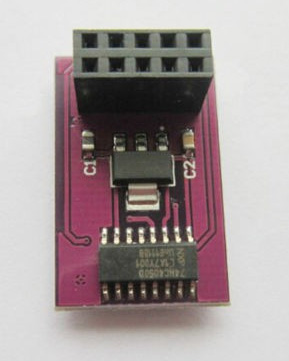

Connecting SD reader.

Reprap is capable of so-called "headless" printing, where "head" stands for a computer. Indeed, let's write commands to the SD card, and then read them using Arduino!

To use SD reader with Arduino, we use special shields:

The only problem, it sticks on Arduino's side, which isn't estethically pleasing:

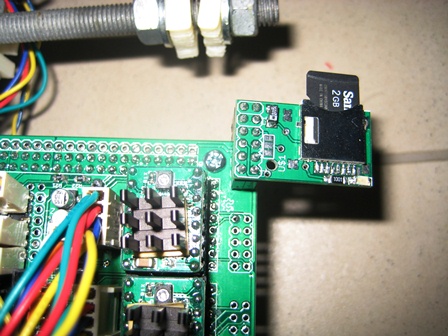

To fix the problem, I designed (download) an SD Holder, that allows to move the shield away from Arduino, and to glue it to the side of an Arduino holder, or to the rod (any rod):

As you can see, I used a home made wire, instead, you can buy "SD card extender".

The photos above (regarding the SD-reader) are from my manual on assembling Prusa i2. In Reprap Next I went one step further: I removed the part of a holder that was supposed to be used to attach it to threaded rod, and glued the rest to Arduino holder:

To do headless printing, you need to: save a file containing G-codes on SD card's root, depending on the firmware (see below) it should be called init.g or auto0.g, then insert the SD card into the Reprap's reader, and then to turn on printer's power. Do not feel bad if nothing happens: it takes some time for the heated bed to reach the working temperature.

A convenient lifehack, one that can, by the way, destroy your appartment if you get distracted, is to put a towel at the print bed, to make heating faster. You need to be around though, to remove the towel before extruder goes down, or it will damage or combust the towel/printer/appartment.

The look..

At this stage our printer is ready to go, except it looks like a doom's day machine. Our task is to hide wires to make it more or less neat. As I mentioned above, you can use "PC Neat" wires wrapper, that comes in different colors and is a rather convenient in terms of adding/removing.

Software.

There is nothing more discouraging, then to find ten incomplete guides instead of a single complete one. With all my respct to the open source development model, the chaos here is unbelievable, compared maybe only with the mess in the commercial software development field.

So we are going to take a different way.

1. Download Arduino's software. This is surprisingly straightforward, just take it from official site, follow the "download" link for your operational system. You have to install this software on your computer, in order to use it later to install so-called "firmware" on Arduino. I used this version.

2. Download Sprinter. This is a set of files which Arduino's soft (see 1) will turn into Arduino's firmware. If you need the last version, use Google, if you want the version I used, here it is. Note, that this is the version I modified for a specific printer (Next or Pyramid), so in theory, if you follow my steps, it will work "out of the box".

3. Connect Reprap to a computer using USB cable. It will either be recognized, or not. Go to Device Manager (I am talking about Windows here, if not, you are on your own, sorry), find your device. In Ports (COM & LPT), find your printer, or in "Other Devices" find an unrecognized "Unknown Device". Click on it with the right mouse button, choose "Update Driver Software" - "Browse my computer for Driver software". Select "arduino.inf", located in "Drivers" folder of Arduino Software (not in "FTDI USB Drivers" sub-folder). At this point, Windows should manage. If not, find in Windows and ENABLE old/deprecated drivers (yes, they disable some USB devices!) If still no luck, copy and try Arduino old drivers.

4. Start arduino.exe (see. 1), open Sprinter.pde in Sprinter directory. It will open another copy of arduino.exe, you can now close the first copy. Don't ask :)

Press an arrow icon on a toolbar, the software will be compiled and sent to Arduino.

Important note: to do steps 1 - 4, you don't need PSU, USB connection will provide sufficient power to Arduino. Especially considering, that we haven't tested anything yet.

5. Copy Repetier Host to your computer. There are countless programs that can take STL file, turn it into G-codes and send it to 3d printer, I like Repetier. Lately they abandoned opensource model, and even began displaying commercials. Here is the last "fair" version: Repetier Host.

Start Repetier Host, turn on printer, in Repetier Host, click "Connect" on toolbar. Switch to the last tab (manual), and test motors, extruder and heaters, one by one. Be ready to unplug it on any sigh of an emergency, which is smell, shieds overheating (test shield's radiator with finger), loud (too loud) motors and when the motor does not stop after hitting the stop.

Test print.

Prepare an STL file for a simple test (cube 2x2x1), and print it, first from Repetier, then from SD card. Do not forget about a glass covering a heated bed. A glass should be heat resistant borosilicate, or sitall one, use "presentation clips" to hold it against the heated surface (see printer's photo). Note that clips should not bump on anything as heated bed moves.

The plastic does not hold on glass well. You print - it falls off, before you finished. People use capton tape (search "reprap tape"), or hair spray. I use hair spray or sitall glass. Be careful, if your hair spray smells perfume, your house will smell... exotic.

Conclusion.

If you like this site, please consider "liking" it in social networks. Good luck :)